For those newcomers, here’s how it got its start. Those who live and breathe HDD are familiar with the industry’s origins. They have to specify and design the job to be done with a different method,” Levings says. “In the early days, the knowledge wasn’t there, the tools weren’t there, the experience wasn’t there and, quite frankly, there wasn’t a lot of trust with the engineers who were designing the infrastructure and that’s where it has to start.

One recent intersect bore exceeded 17,000 ft in Hong Kong! Intersect HDD applications gave project designers and drillers the capability to more than double the length of projects. Today, installation bores are routinely in the thousands of feet, with product diameters upward to 48 in. The industry started off with shorter lengths and smaller diameters. It went from being a novelty and by 2000 when the dot com boom was happening, there were thousands of rigs being produced every year.”

“ grew exponentially during those years, about 20 to 50 percent each year. “ is most definitely a maturing industry but it is in no way mature,” says Vermeer Industrial Solutions president Doug Hundt, who has been in the industry for 25 years, coming in as HDD just started taking off. Design engineers, once slow to adopt the method, began integrating the application in project specifications as acceptance took hold. In the classrooms and labs, HDD research and education ramped up at the university levels. Tooling, locating and steering systems, drill pipe and drilling fluid technology all vastly improved at the same time. Construction brands Vermeer, Ditch Witch, and American Augers led the way in rig technology, followed by many others, with a back and forth in upgrades and improvements. New technologies came in rapid fire succession. HDD started off slowly, coming into prominence in the mid-1990s as the telecom/fiber-optic boom propelled HDD into the construction lexicon. Globally it’s a multi-billion-dollar industry, not just in rig sales but in the amount of work that contractors do and the amount of money that HDD saves owners who are installing the networks.” “It’s the largest percentage of any underground installation method.

Horizontal directional drilling jobs professional#

“The adoption of HDD is widespread in a number of industries and being used for things we never dreamed of when we began,” says Richard Levings, longtime industry professional and product manager at Ditch Witch and American Augers. Once unique to see a directional drill working in your neighborhood, they are now routinely seen drilling in neighborhoods everywhere, leaving behind minimal social, environmental and restorative impacts.

Horizontal directional drilling jobs install#

HDD is used to install natural gas, water, wastewater, electric, telecommunication and fiber-optic lines every day across North America and around the world. HDD encompasses more than just underground infrastructure, including manufacturing, contracting, engineering, and educational sectors, as well. The total cable route from the offshore converter station BorWin kappa to the substation on land is 235 kilometres long.Once unknown or met with skepticism, HDD today is a multi-billion-dollar, global industry - that continues to grow with each year. Offshore, BorWin6 will be linked to the BorWin kappa platform via 66 kV three-phase cables, which eliminates the need for the transformer stations that were previously required in each wind farm and the 155 kV three-phase cables that were previously used to connect to TenneT’s offshore platforms.

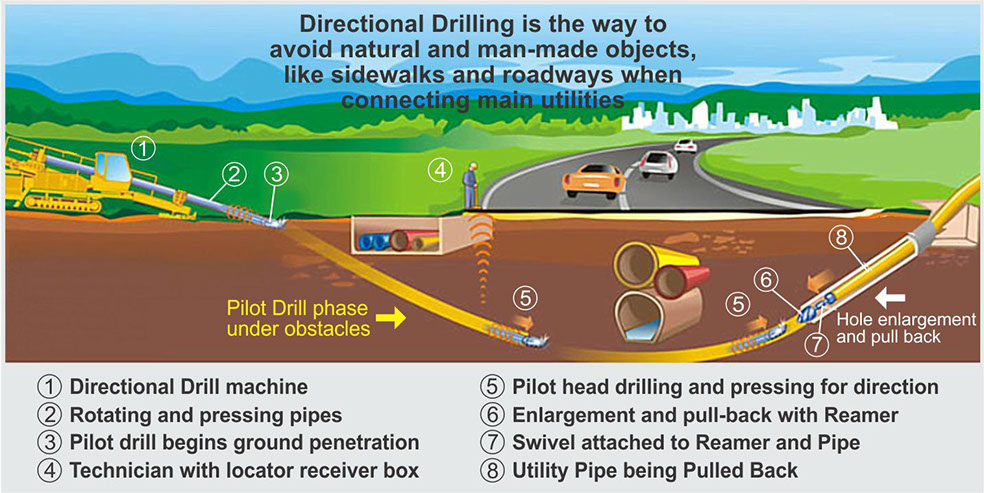

The onshore cable will be installed parallel to the existing routes of the HelWin1+2 and SylWin1 connections, whose onshore converters are also located in Büttel. The cable laying work is expected to start in 2025 and BorWin6, which will have the capacity to link 980 MW of offshore wind off the island of Borkum to the grid, is scheduled to go online in 2027.īorWin6 will connect to the grid on land through an onshore converter station in Büttel, with the now-contracted Bohlen & Doyen tasked with installing the 45 kilometres onshore section from the landing point in Büsum, Schleswig-Holstein, to the future converter station in Büttel.Īccording to the German company, due to various dyke and watercourse crossings, as well as sensitive ecosystems along the onshore route, around 30 per cent of the underground cable connection will be realised using the latest trenchless horizontal directional drilling (HDD) technology.

0 kommentar(er)

0 kommentar(er)